- PLANT SIMULATION TOOLS 64 BIT

- PLANT SIMULATION TOOLS SOFTWARE

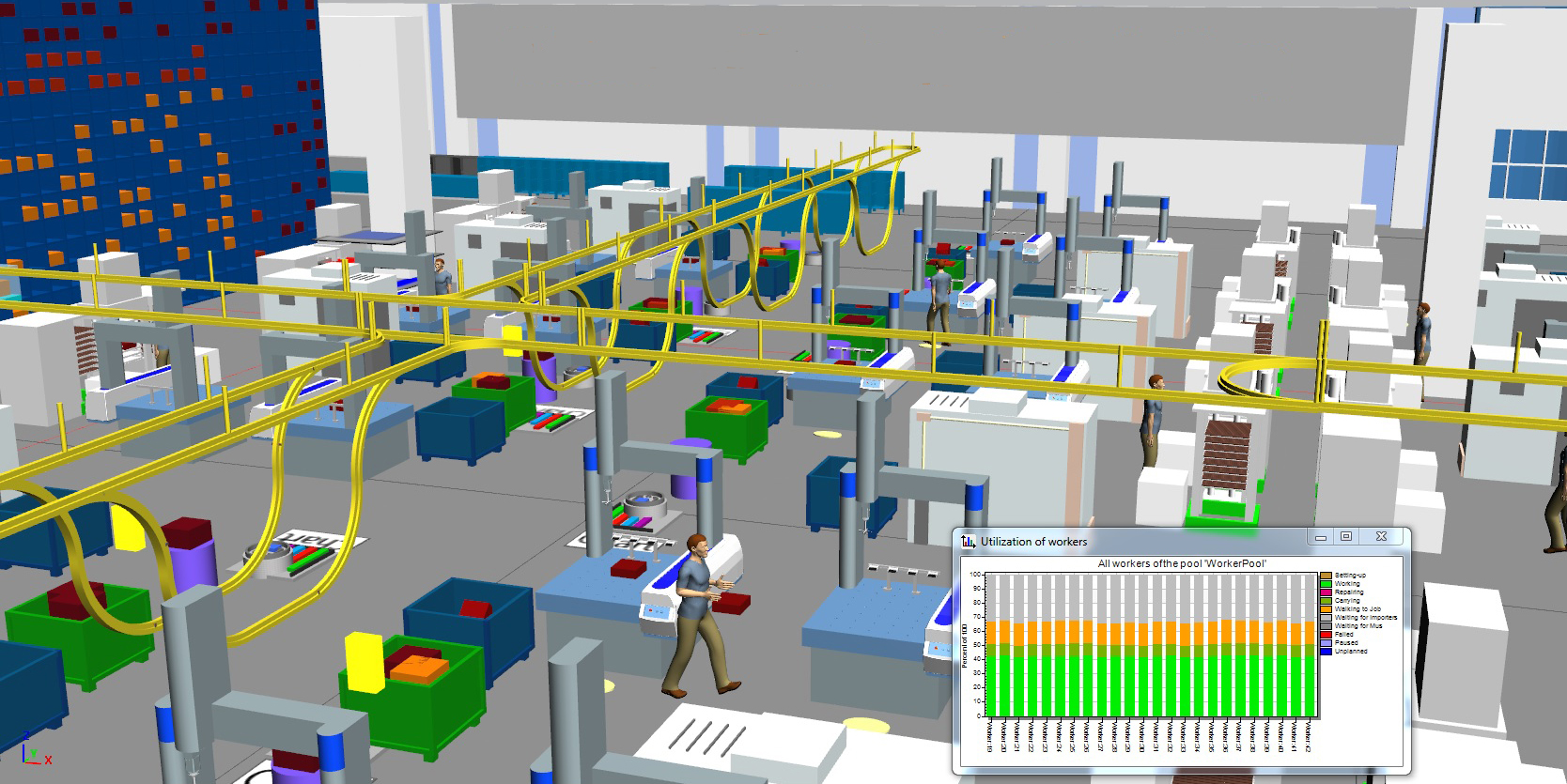

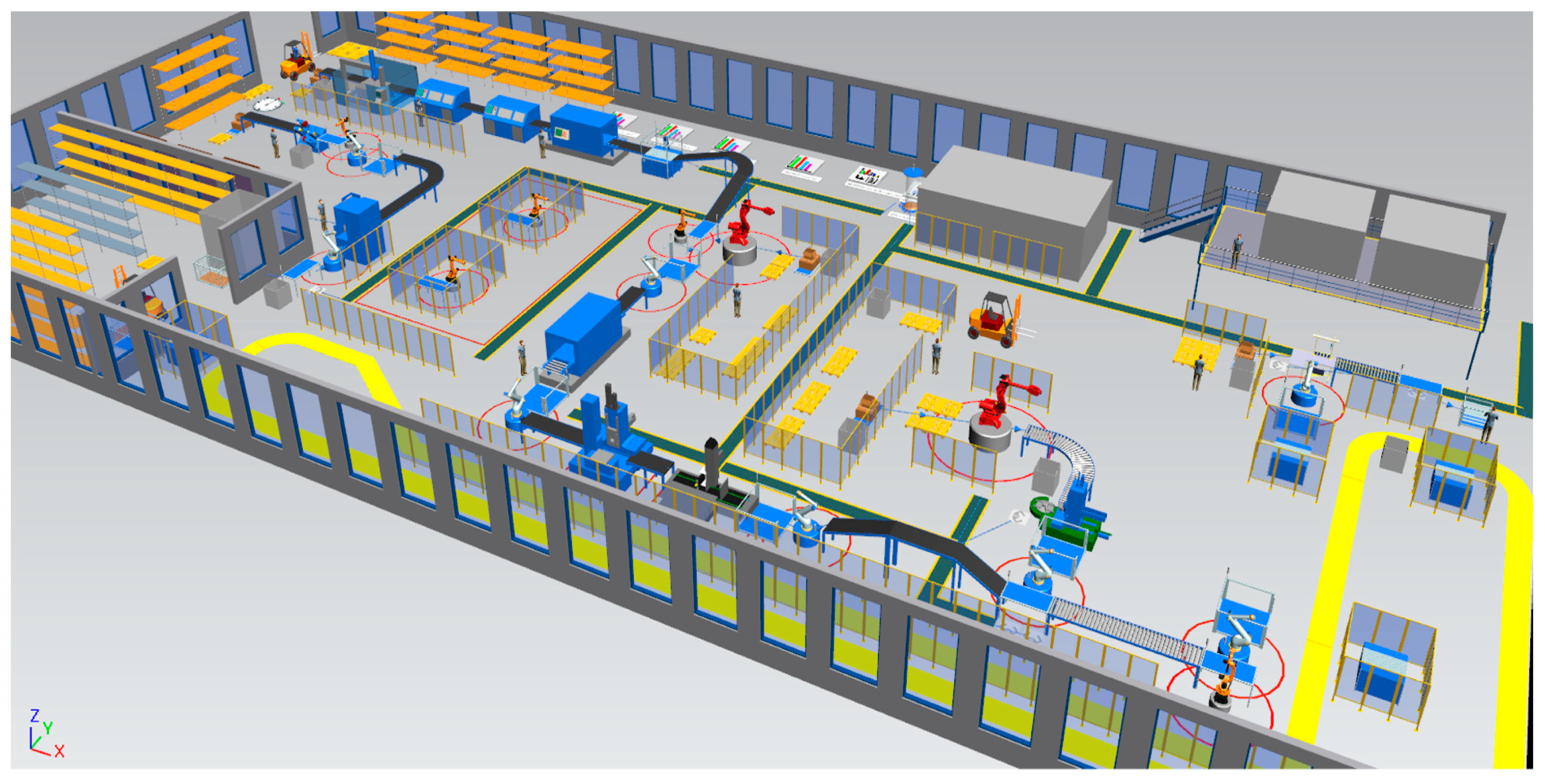

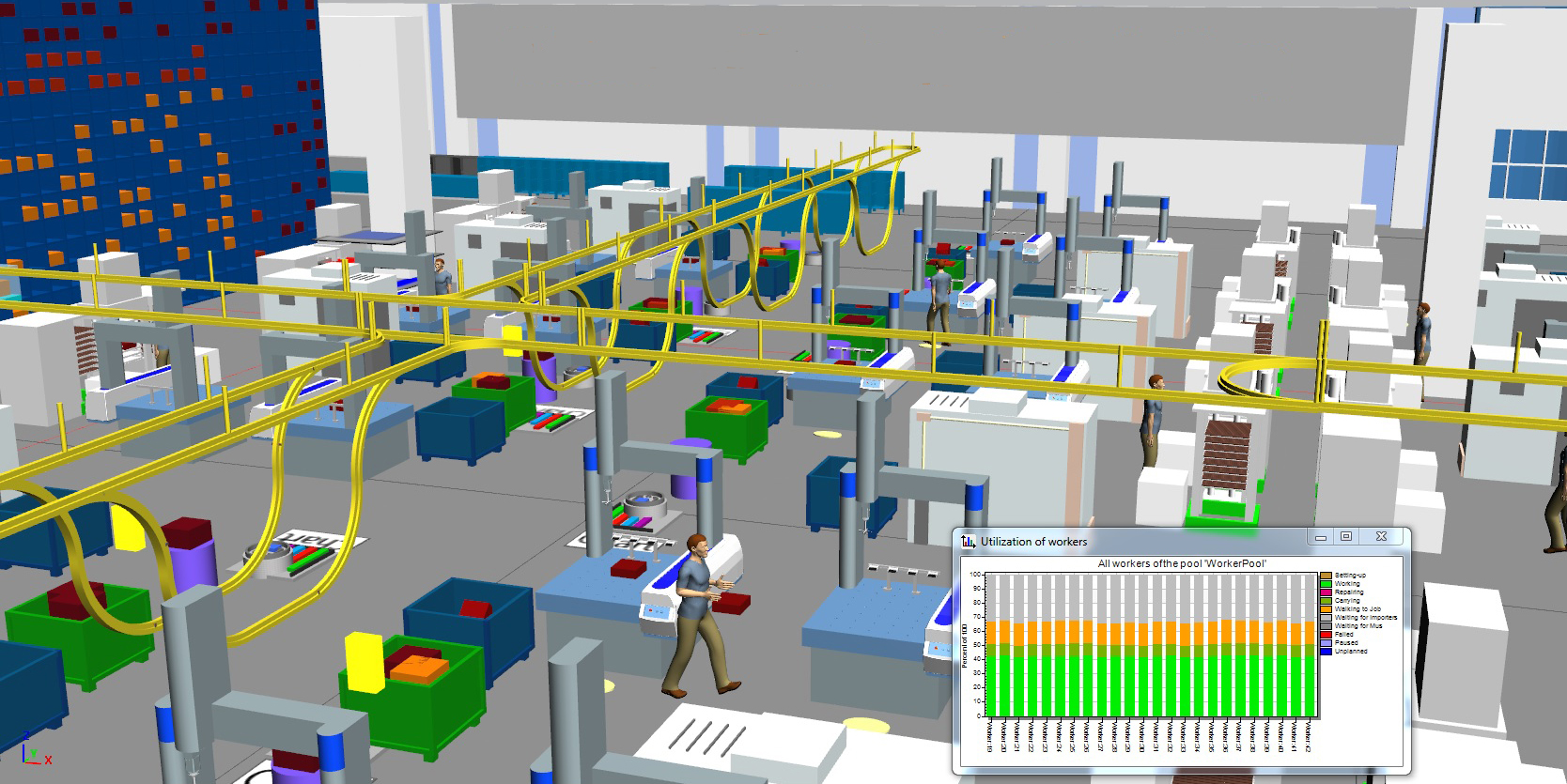

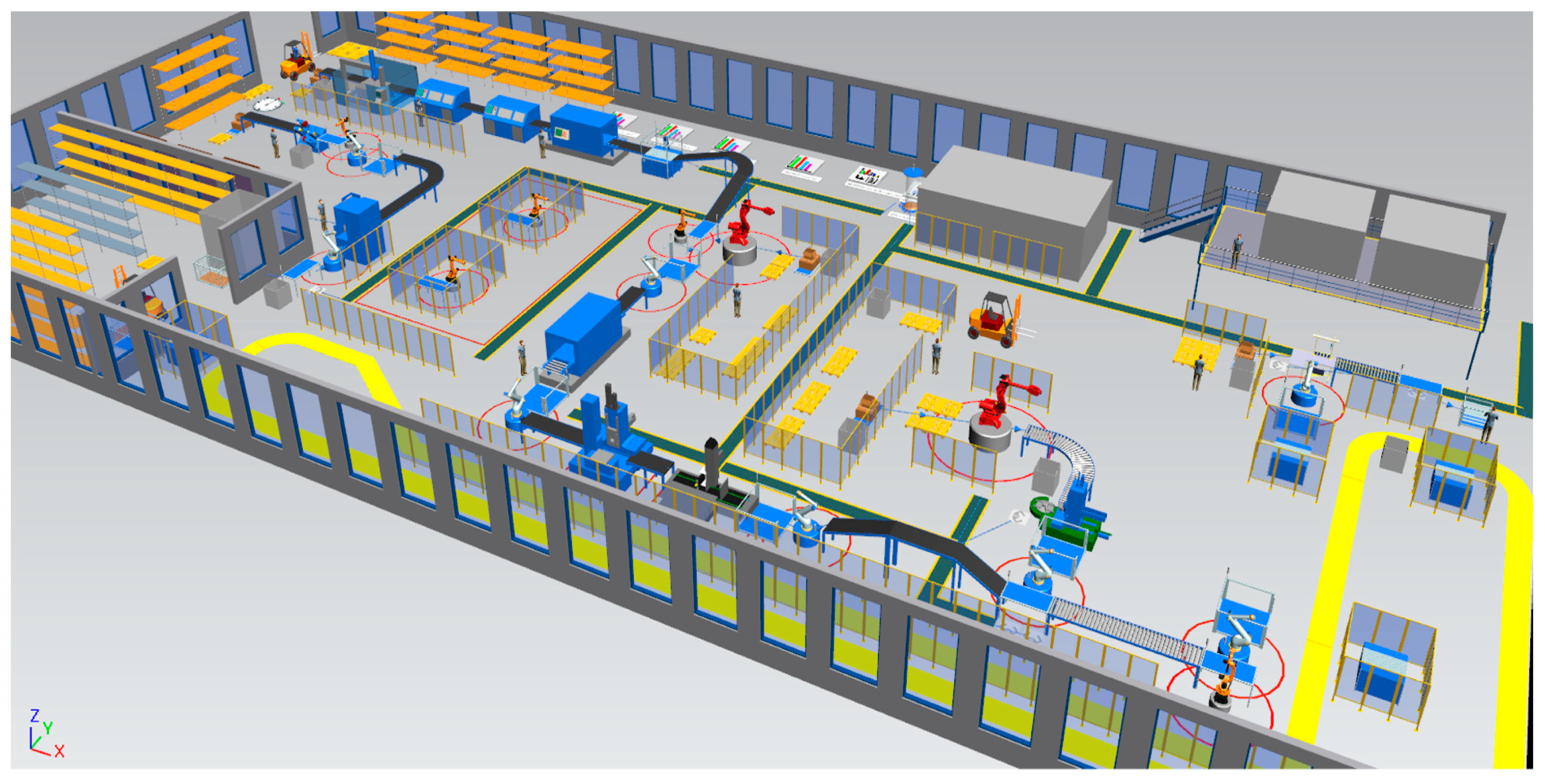

Provides comprehensible analysis tools for detecting bottlenecks (Bottleneck Analyzer), for tracking the flow of materials ( Sankey diagrams) or for detecting over-dimensioned resources (Chart Wizard).  taking over layout data from Autocad, Microstation, Factor圜AD, etc. importing data from PLM systems or be used during. Integration: Plant Simulation is part of the Digital factory and supports. Openness for importing data from other systems, such as Access or Oracle data bases, Excel worksheets or from SAP. This facilitates a Top-down and bottom-up design approach. Hierarchy: Complex structures can be created very clearly on several (logic) layers. This enables users to build complex models faster, easier and with a clearer structure. Polymorphism: Classes can be derived and derived methods can be redefined. As opposed to a copy, any change to an object class within the library is propagated to any of the derived objects (children). Inheritance: Users create libraries with their own objects, which can be re-used. The user can switch between the available languages. The user can create individual Dialog boxes using double-byte characters and offering individual parameterizations. Plant Simulation is available in English, German, Japanese, Hungarian, Russian and Chinese. In most cases the solutions resulting from these calculations were hard to understand and were marked by a large number of boundary conditions and restrictions which were hard to abide by in reality. Before powerful computers were available, most problems of material flow simulation have been solved by means of queuing theory and operations research methods. These processes resist simple mathematical descriptions and derivations due to numerous dependencies. These processes are characterized by non-steady material flows, which means that the part is either there or not there, the shift takes place or does not take place, the machine works without errors or reports a failure. In general the Material flow analysis is used when discrete production processes are running. The Computer model allows the user to execute experiments and to run through 'what if scenarios' without either having to experiment with the real production environment or, when applied within the planning phase, long before the real system exists. Using simulation, complex and dynamic enterprise workflows are evaluated to arrive at mathematically safeguarded entrepreneurial decisions.

taking over layout data from Autocad, Microstation, Factor圜AD, etc. importing data from PLM systems or be used during. Integration: Plant Simulation is part of the Digital factory and supports. Openness for importing data from other systems, such as Access or Oracle data bases, Excel worksheets or from SAP. This facilitates a Top-down and bottom-up design approach. Hierarchy: Complex structures can be created very clearly on several (logic) layers. This enables users to build complex models faster, easier and with a clearer structure. Polymorphism: Classes can be derived and derived methods can be redefined. As opposed to a copy, any change to an object class within the library is propagated to any of the derived objects (children). Inheritance: Users create libraries with their own objects, which can be re-used. The user can switch between the available languages. The user can create individual Dialog boxes using double-byte characters and offering individual parameterizations. Plant Simulation is available in English, German, Japanese, Hungarian, Russian and Chinese. In most cases the solutions resulting from these calculations were hard to understand and were marked by a large number of boundary conditions and restrictions which were hard to abide by in reality. Before powerful computers were available, most problems of material flow simulation have been solved by means of queuing theory and operations research methods. These processes resist simple mathematical descriptions and derivations due to numerous dependencies. These processes are characterized by non-steady material flows, which means that the part is either there or not there, the shift takes place or does not take place, the machine works without errors or reports a failure. In general the Material flow analysis is used when discrete production processes are running. The Computer model allows the user to execute experiments and to run through 'what if scenarios' without either having to experiment with the real production environment or, when applied within the planning phase, long before the real system exists. Using simulation, complex and dynamic enterprise workflows are evaluated to arrive at mathematically safeguarded entrepreneurial decisions. Plant Simulation is a Material flow simulation Software ( Discrete Event Simulation DES Software).

2.1 Calculation of enterprise characteristics.It is one of the major products that dominate that market space. Plant Simulation is used by individual production planners as well as by multi-national enterprises, primarily to strategically plan layout, control logic and dimensions of large, complex production investments. The application allows comparing complex production alternatives, including the immanent process logic, by means of computer simulations. Within the Plant Design und Optimization Solution the software portfolio, to which Plant Simulation belongs, is - together with the products of the Digital Factory and of Digital Manufacturing - part of the Product Lifecycle Management Software (PLM). Using Tecnomatix Plant Simulation, users can optimize material flow, resource utilization and logistics for all levels of plant planning from global production facilities, through local plants, to specific lines. Plant Simulation is a computer application developed by Siemens PLM Software for modeling, simulating, analyzing, visualizing and optimizing production systems and processes, the flow of materials and logistic operations.

Windows 7&8 32 bit + 64 bit /Windows XP/Vista

0 kommentar(er)

0 kommentar(er)